DIGICASE - DIGITAL TECHNOLOGY CREATES NEW OPPORTUNITIES

FOR CASING PRINTERS

For many years printers of artificial food casings have identified the potential benefits of being able to access ‘short run’ production capability, including instant image change with virtually no material waste or down-time.

Through a unique cooperation between Resino Trykfarver and KPG Europe and combining the experience and skills of both companies, DIGICASE - a digital system for printing casings in full colour, plus white, will be launched at IFFA and Labelexpo 2019.

Resino has finalized a development programme, adapting their well proven flexographic UV curing ink technology for printing artificial casings, into an inkjet applicable variant, RESUCAT ® 220 series.

Needless to say, casings printed with this inkjet variant can be treated in the conventional way in terms of shirring, filling and autoclave processing. Naturally, the RESUCAT®220 ink series is also low migration and low odour and has no need for primer or overprint varnish.

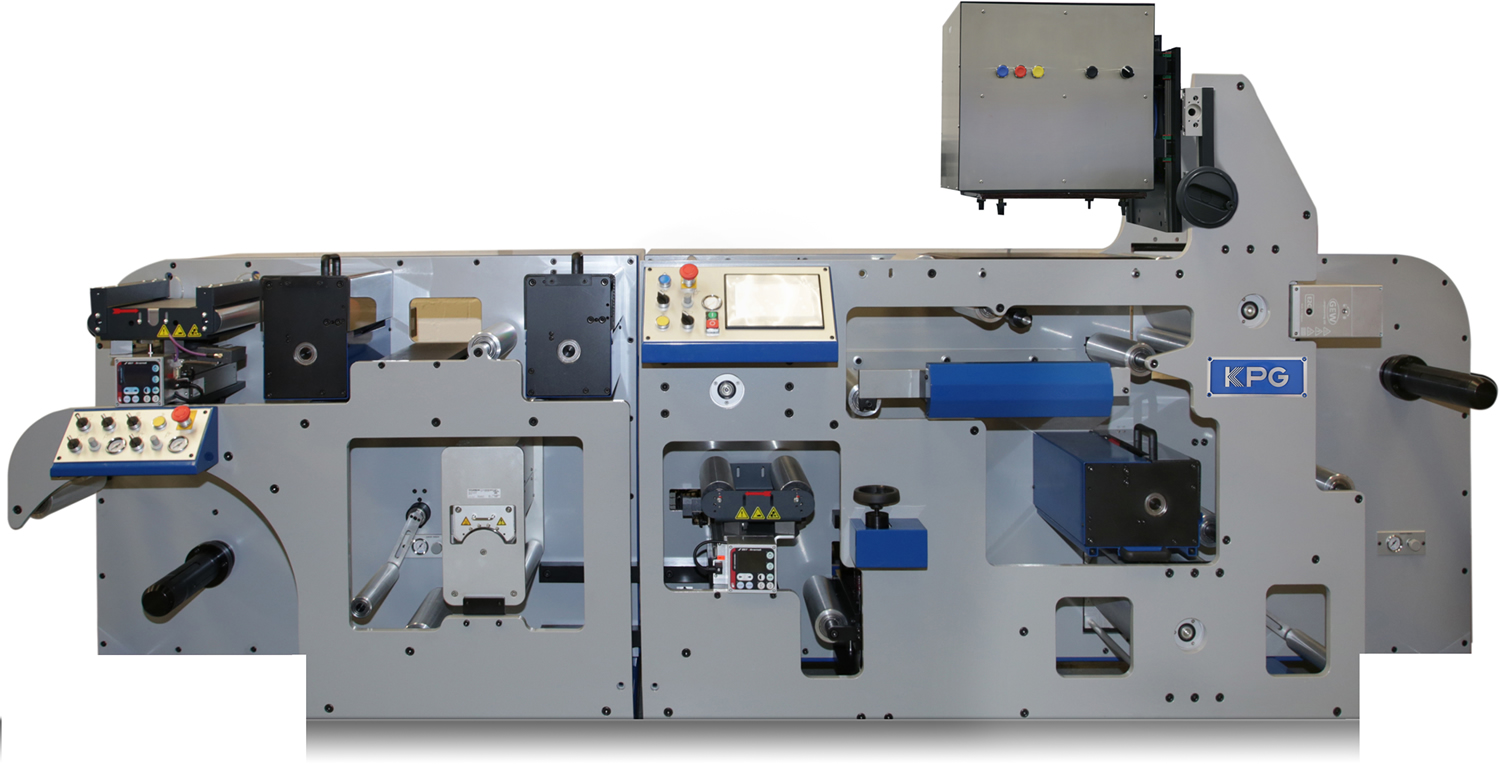

Designing the new digital system, KPG has been able to maximise the vast experience gained by

supplying dual-pass flexo casing presses worldwide for many years. With pdf handling, instant data changes, choice of print resolution and production speeds (600 X 600dpi and up to 100m/min depending on design); ‘short runs’ are now a reality for casing printers. Optional features include fully automatic production and a CID (chilled central impression drum) version will also be available.

Development and extensive trials by the two companies over the past two years have culminated in this new technology being launched in the spring.

Find us at Labelexpo 2019 Stand 3E25

24.04.19