DIGICASE CREATES NEW OPPORTUNITIES FOR CASING PRINTERS

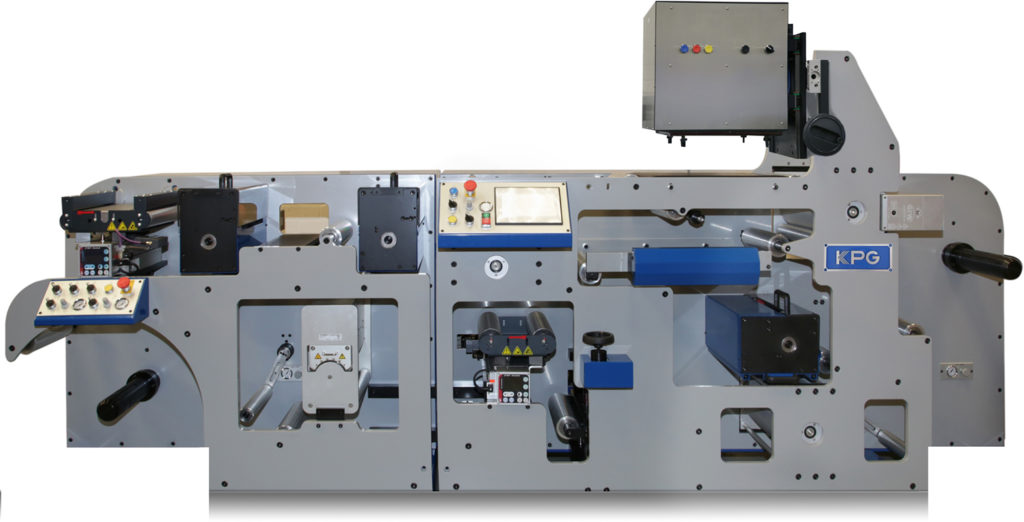

FOR MANY YEARS PRINTERS OF ARTIFICIAL FOOD CASINGS HAVE IDENTIFIED THE POTENTIAL BENEFITS OF BEING ABLE TO ACCESS ‘SHORT RUN’ PRODUCTION CAPABILITY, INCLUDING INSTANT IMAGE CHANGE WITH VIRTUALLY NO MATERIAL WASTE OR DOWN-TIME. DIGICASE IS A DIGITAL SYSTEM FOR PRINTING POLYAMIDE CASINGS AND BAGS, FOOD PACKAGING FILMS AND PLASTIC CASINGS IN FULL COLOUR, PLUS WHITE.

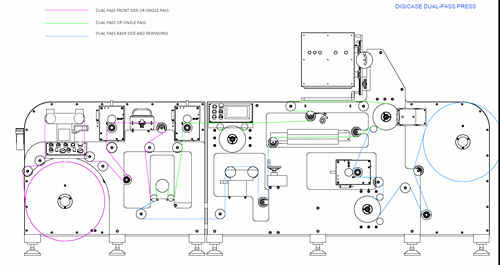

With immediate variable data changes, the technology is ideal for JIT orders, language and code variations, as well customer proofing. Dual-pass and single-pass printing in four web widths, with a choice of print resolution and operating speeds optimises production flexibility.

User friendly software provides a DRAG – DROP – PRINT sequence for instant job changes. Incorporating the very latest user interface currently available, job changes, the addition of variable data and pdf handling is effortless. Simply by scanning a flexo printed image and adding this to an existing pdf design, it is possible to match digitally printed colours to flexo printing.

Print heads to suit specific applications such as; Kyocera, Xaar, Seiko or Ricoh.

Digitally printed casings meet existing meat packaging processing standards, whilst the eco-friendly technology of DIGICASE ensures lower emissions, reduced power consumption and virtually no waste.

*Based on 260 version.

Technical Information

| PRINT WIDTH | *Single pass: min/max 10mm - 260mm *Dual pass: min/max 10mm - 125mm |

| WEB WIDTH | *Single pass: 260mm (max) *Dual pass: 125mm (max) |

| PRINT SPEED | Maximum: 150m/min (Variable, depending on design, resolution and substrate) |

| RESOLUTION | 600 X 600dpi (at 50m/min) 300 X 600dpi (at 100m/min) 150 X 600dpi (at 150m/min) |

| SUBSTRATES | From mono-layer wiener casings to multi-layered polyamide casings, packaging films and plastics |

| FRONT-TO-BACK REGISTRATION | Manual web compensator |

| MECHANICAL SPEED | 200m/min |

| ROLL/CORE SIZE | Standard – 450mm dia rolls with 3” ( 75mm) cores |

| INKS/CURING | GEW Rhino E2CHP with mercury or iron doped lamps. 180 w/cm. |

Features

- Ultra-sonic web guides

- Corona treater

- Service ‘Cube’ also containing ancillary equipment

- Heater/chiller unit, GEW power supply, extraction fan and touch screen

- Vetaphone power supply, extraction fan and touch screen

- Mains power board

- DIGICASE is manufactured to meet current European Health & Safety Standards

Options

- Fully automatic/semi-automatic configuration

- Turret rewinder

- CID (central impression drum) configuration

- 360mm web width

- Additional digital print heads, including white

- Expanded colour management suite for fine/precise colour adjustments (ColorGATE)

- 6” (152mm) core adaptors

- Increased roll diameter 600mm

- Flexo varnish unit for special effects such as 'patch' decoration

- Video inspection system

- Turn-bar with web compensator

- Web cleaner

- Internet diagnostics

- After-sales Customer Support Packages