EUROFLEX CASING

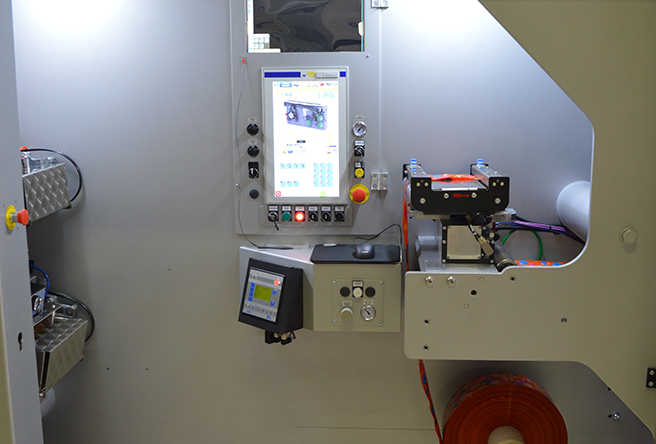

SPECIFICALLY DESIGNED FOR PRINTING ARTIFICIAL FOOD CASINGS AND POUCHES, AS WELL AS WIENER PRODUCTS, KPG PRESSES COMBINE HIGH QUALITY PRINTING WITH NON-STOP PRODUCTION 24/7.

Now available, DIGICASE DP press for digitally printing artificial casings on both sides.

With only minor changes in specification, KPG casing presses can also be used for printing self-adhesive labels, ABL/PBL barrier laminates and films, enabling maximum press utilisation.

Worldwide installations with comprehensive after-sales support.

Technical Information

| PRINTING | 4 – 18 colours, single and dual-pass production, open or closed chambers |

| WEB WIDTHS | 210mm, 260mm, 400mm and 520mm |

| CONFIGURATION | Fully-automatic unwind and rewind, Fully-automatic unwind with integral 2 x rewindS, Less waste and reduced press down-time |

| INKS | UV cationic & free radical, solvent and water based inks, Using UV curing, hot-air and/or IR drying |

Features

- Robust construction. Frame built from 170 and 80mm cast iron for vibration free operation

- Temperature controlled steel central impression drum

- Chill rollers

- Turn-bar system with web compensator

Options

- Servo driven presses. All web widths

- Scraper system with vacuum removal of excess ink for 3600 printing of all round designs

- Auto-register control for front-to-back printing

- Internet diagnostics

- Twin camera system for both-sides print quality checks

- Double-sided corona treater and web cleaner